The construction of the boiler is progressing well, but to determine its exact position on the frame, it’s useful for the smokebox to be completed first. From there, the exact height and location on the frame can be measured.

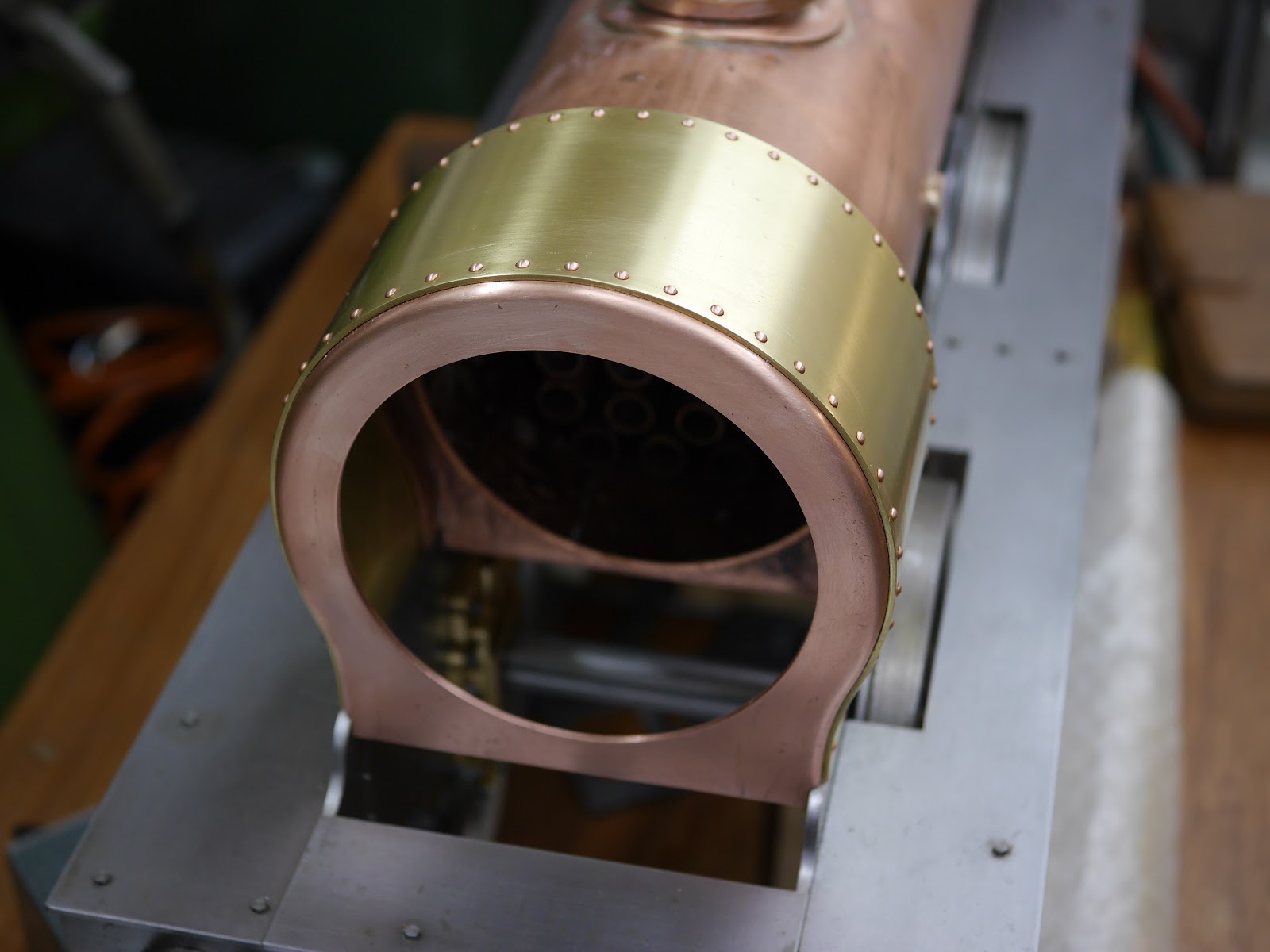

Unlike my other locomotives, this smokebox is not made from a steel tube, but is constructed from sheet material. This is because this smokebox does not have a separate smokebox saddle; instead, the smokebox and the saddle form a single unit.

The fronts are shaped from 2 mm copper sheet, and the outer shell is bent from 1.5 mm brass sheet. The whole assembly is riveted with copper rivets.

The original Y14 locos featured several types of smokeboxes, all made from sheet steel. These were initially riveted with flush rivets, later with snaphead rivets, and on the preserved locomotive, the construction is even welded.

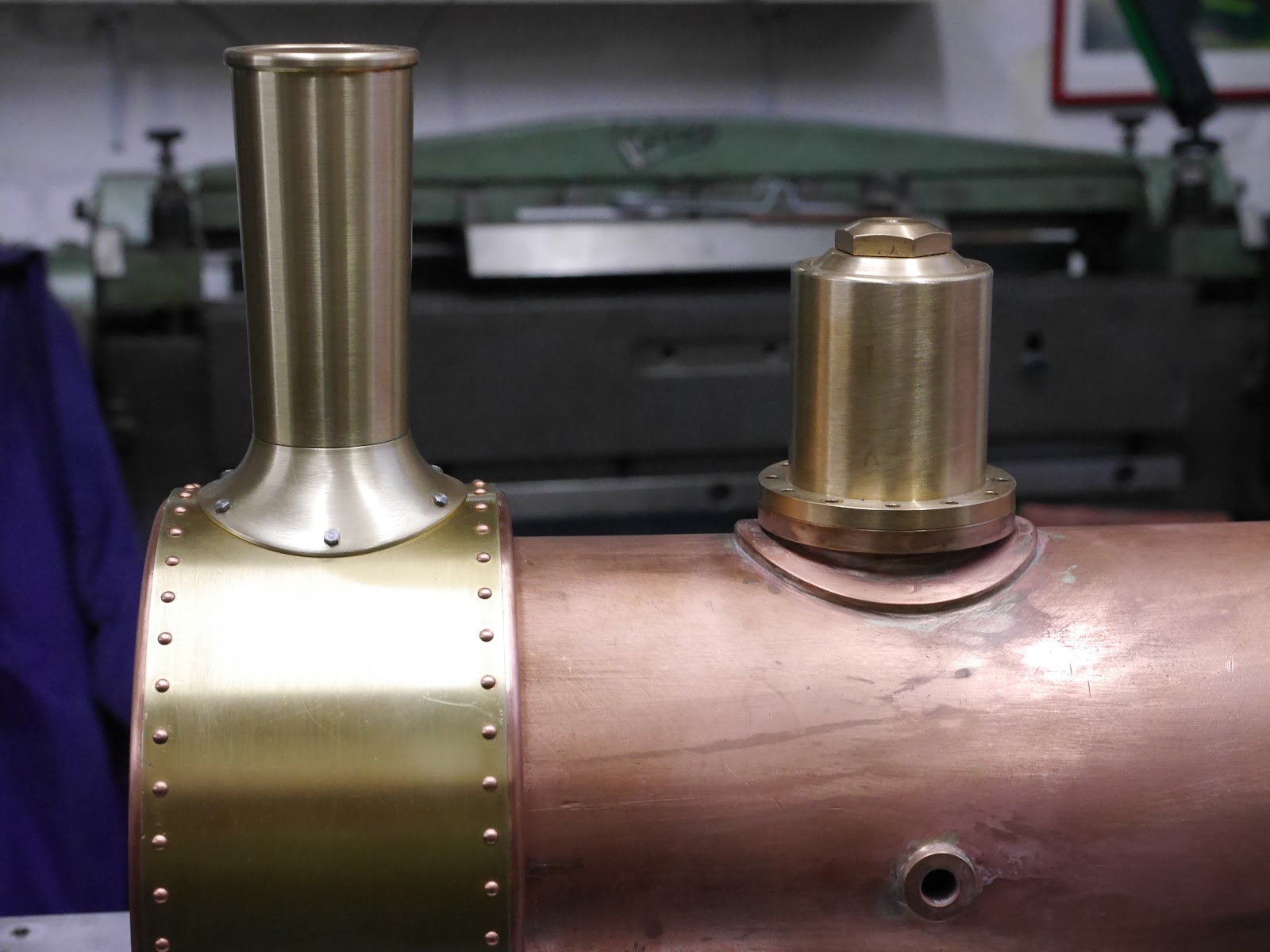

Over the locomotive’s lifespan, various types of chimneys were used. The Great Eastern Railway applied the so-called stovepipe chimneys, while the London and North Eastern Railway mostly used a cast chimney with their standard shape and a lip at the top.

The smokebox

First step: from 10 mm aluminium a former plate was milled

The contour is milled using light cuts. Two bolts hold the plate directly onto the milling bed.

Two millimeter copper sheet is annealed so that it can be formed around the aluminium plate.

Chain drilling to create the large hole for the boiler barrel (114.5 mm or 4.5 inches)—in hindsight, it turned out to be a lot of work…

.....So for the second hole for the smokebox door, the rotary table was setup.

The small cutout at the bottom is filed by hand according to the drawing’s dimensions. This defines the height of the boiler.

The smokebox wrapper plate is centered and drilled for rivets.

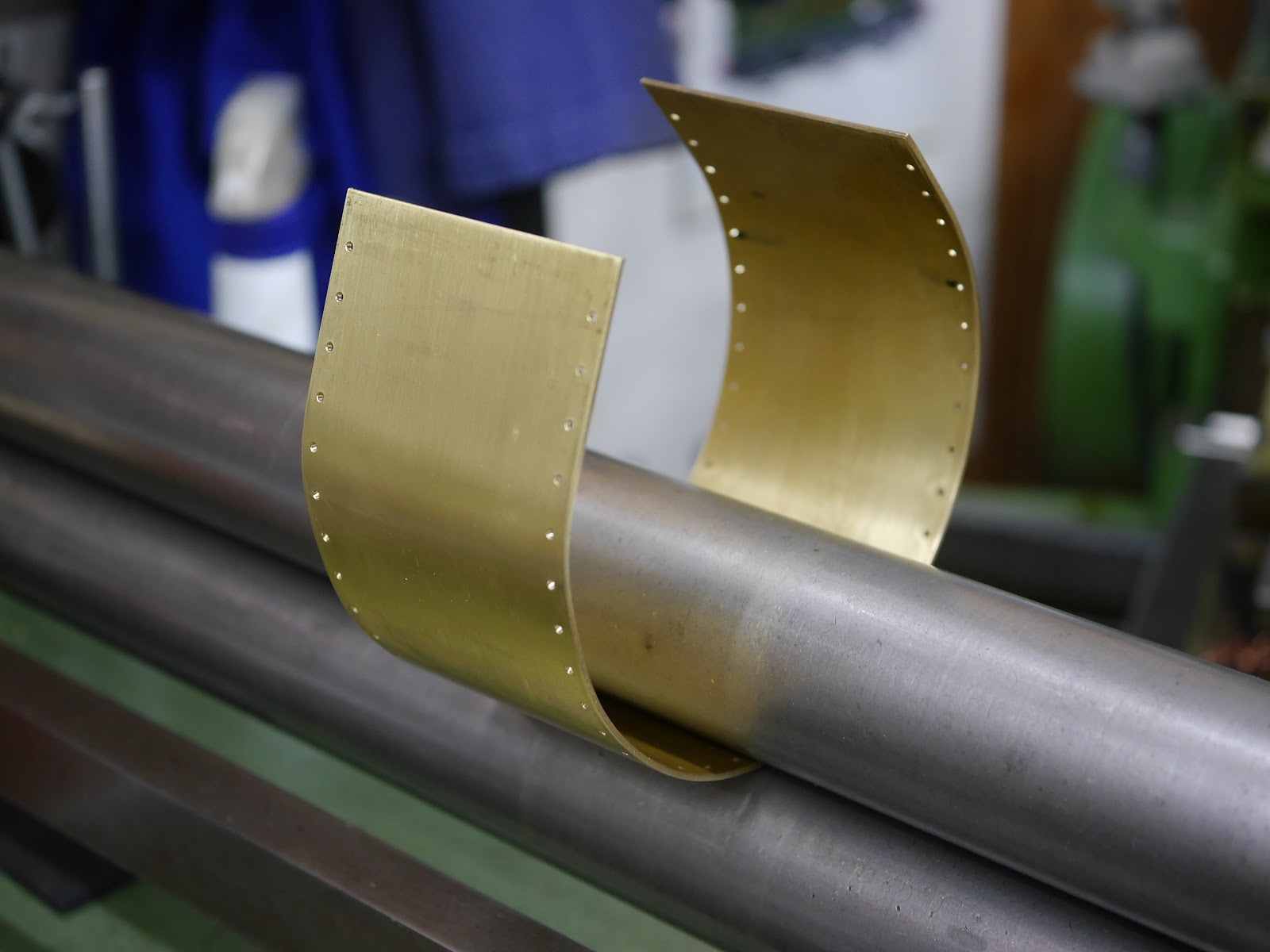

Bending is carried out using the roller bending machine.

The ends are bent outwards over a piece of round bar. It involves a bit of guesswork, with the rivet holes providing some indication of the bend’s position.

The brass plate is annealed only once, before riveting it to the front smokebox door plate.

Held in position with two small clamps, the holes from the brass plate are transferred onto the front side—starting at the center, then placing one rivet to the left and one to the right each time.

The smokebox is temporarily fitted to the frame to check alignment and positioning.

Because the smoke box is made of sheet metal and only riveted, it had to be carefully clamped before boring the 28 mm hole for the chimney. That’s why only small cuts were made each time.

The chimney

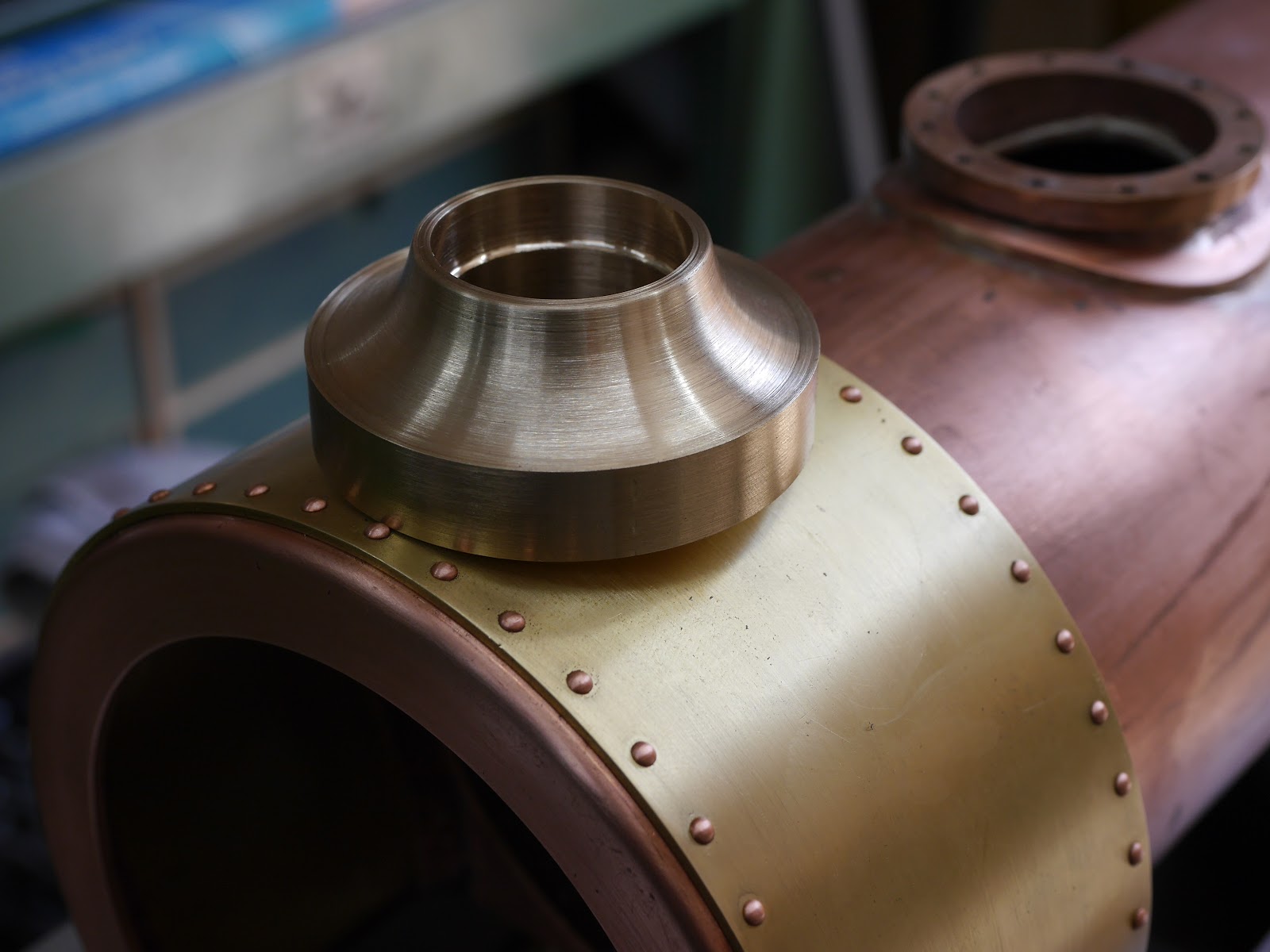

The base is cut from solid brass, which is easier to work with than steel. This is particularly useful when it comes to filing and final finishing.

The first profile was created using a radius tool. Because the tool’s radius was undersized, the shape was formed by carefully maneuvering both the X and Z cross slides. The finished dimensions were checked with a small gauge plate.

A general overview: the base has a diameter of 58 mm.

By soldering the base to a bar, it could be securely held in the milling machine vice for the next operation.

The boring head was now used to machine the large radius at the bottom of the chimney base.

This is where craftsmanship comes into play. Using a coarse half-round file, the second radius is shaped by eye. It takes a relatively long time and requires close attention to where material needs to be removed.

But with a bit of patience, you can get quite far.

The surface is finished with a smooth file and emery cloth to give it a clean and neat appearance.

Holes are drilled to fit the bolts that will attach the chimney to the smoke box.

The 'stove pipe' was turned from a solid bar. I had a piece of scrap brass that was nearly the correct diameter—I needed 41 mm, but settled for a 40 mm piece. Once the chimney is mounted on the locomotive, I doubt the difference will be noticeable.

After turning the outer surface to a 1.8-degree taper, the interior was drilled using the largest bit I have—21.5 mm

The inside was bored to a 2.75-degree taper using a large cutting tool.

With that complete, the base and stack are prepared for soldering.

Silver-tin alloy solder was used.

A final cleaning operation in the lathe.

The chimney, finished in the style of the Great Eastern Railway, is fitted onto the locomotive.

A general view of the locomotive, which already captures the character of a

Great Eastern Railway Y14 class.