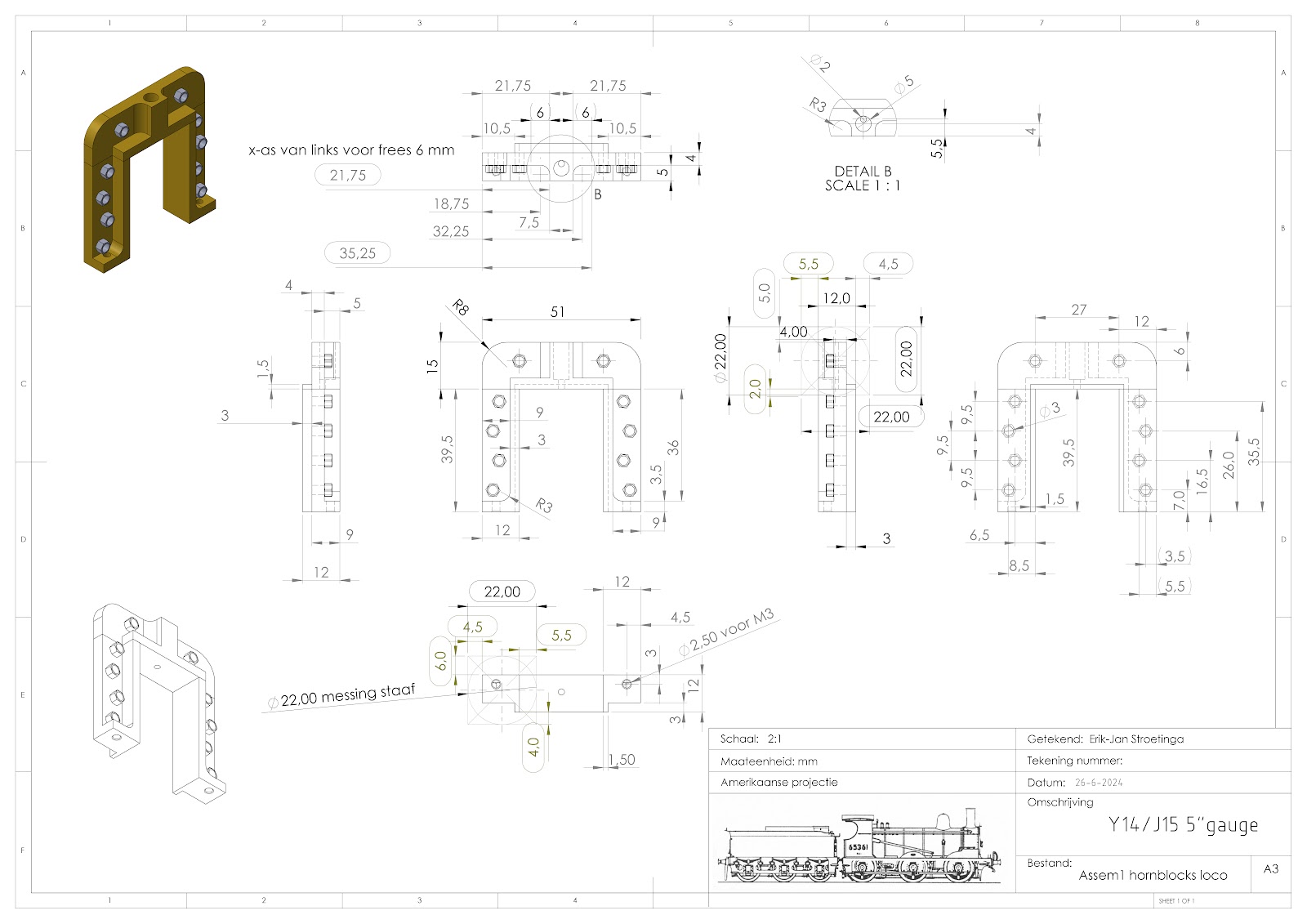

The hornblocks, which have the function of taking up the axle boxes and are made of brass. On the real locomotive they are cast, but for the model they are milled out of brass rods. This is because square material was not available.

Pages

Welcome

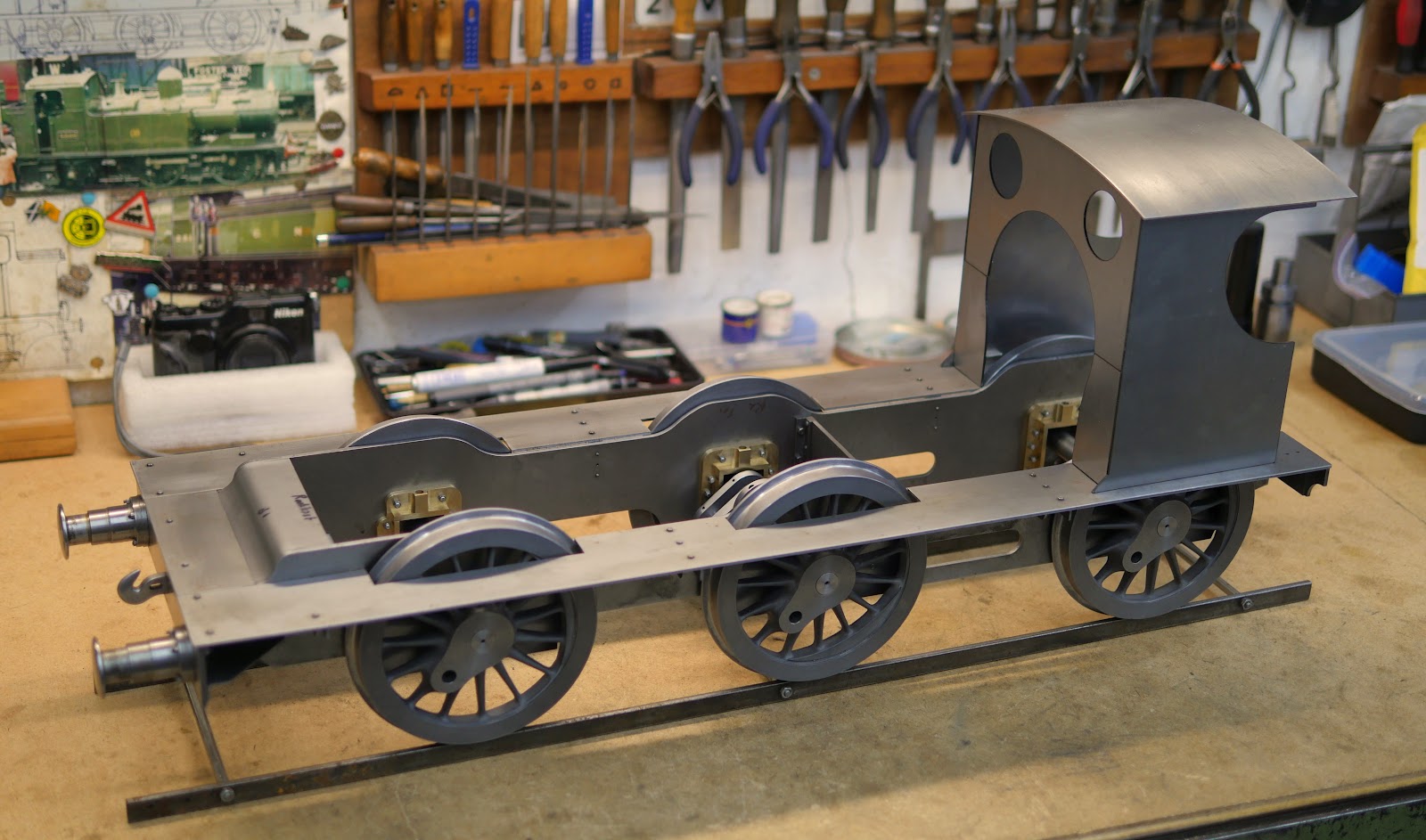

Live steam models on 7¼" gauge of the Württembergische T3 and on 5"gauge Great Eastern Railway Y14 class

Welcome to this blog. It will inform you about the progress of designing and building live steam model locomotives. The blog contains the description of a model Würrtembergische T3 on 7¼" gauge (constructed between 2006 and 2017), the wagons for this loco (built between 2018 and 2022), and the current project a 5" gauge model of a Great Eastern Railway Y14 class loco (started in 2020)

On the left you'll find the index where you can browse the different articles and on the right you'll find all the extras. You'll find a brief description of my other locos on the top tabs.

Click for the direct link to start of construction series below

T3 7¼" steam locomotive

T3 7¼" steam locomotive

Enjoy this site. Erik-Jan Stroetinga. The Netherlands. Europe.

Friday, 12 July 2024

Hornblocks for the Y14

The real thing; the hornblocks are visible at the top of the picture.

The milling machine, now running without any strange noises.

A carton box was used to catch the flying brass chips. Otherwise, they end up all over the place.

Making the first reference face.

With a small edge, they will fit inside the frame.

The top of the hornblocks has a small oil box.

A radius is made with a radius cutter. I didn't have one in 10 mm, as I originally designed, so it was changed to 8 mm. In Solidworks this is quickly done and checked that this change does not interfere with other components.

Drilled oil boxes in the upper parts.

The recently bought bandsaw came to use, for cutting the side parts to length.

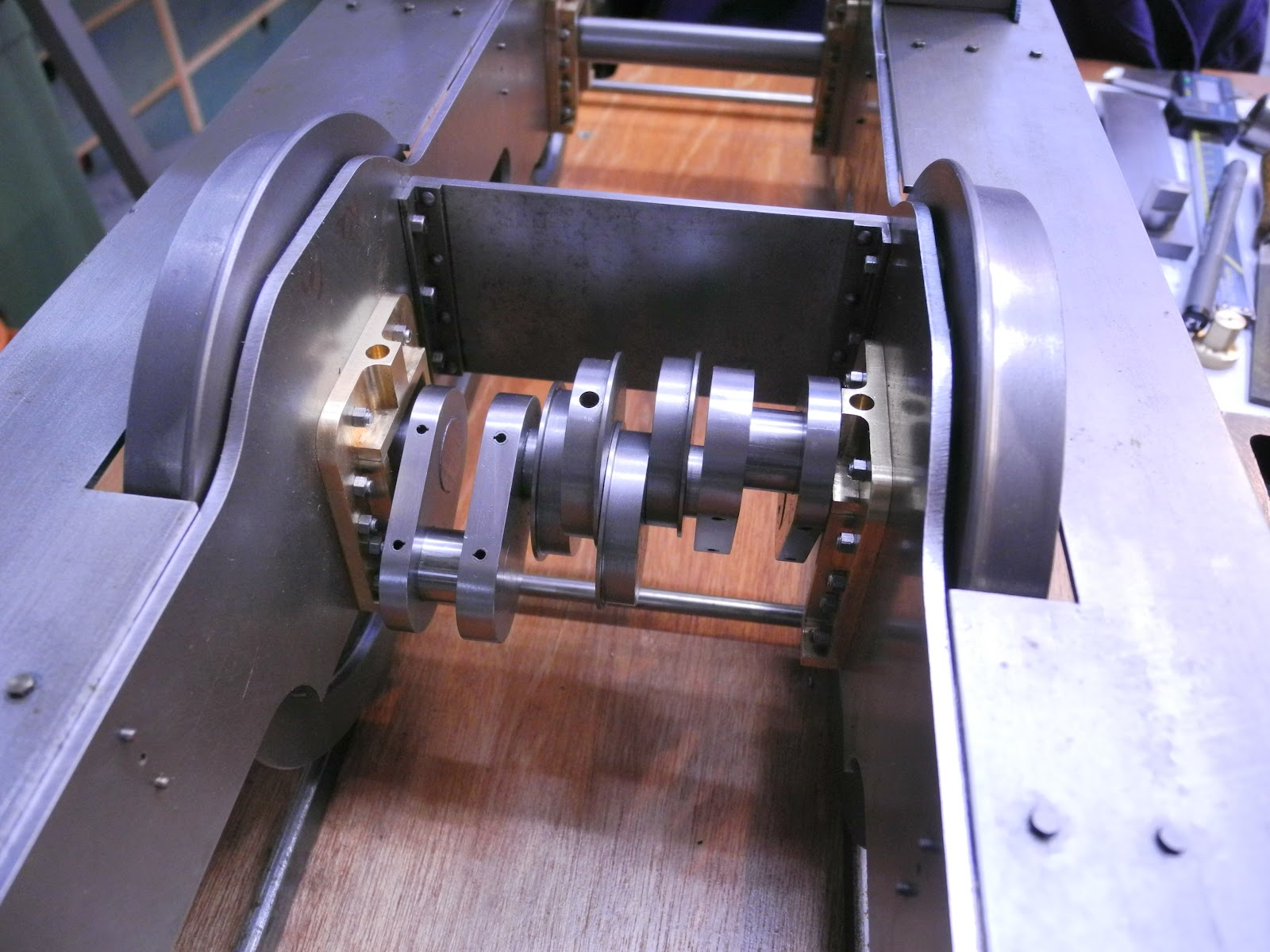

An orderly test fitting; this way I'm able to keep the left- and righthand part apart

With a carbide mill the sides are cut.

Drilling 3mm holes has been done on the drilling machine.

The horns are than used as a drilling guide for the holes in the frames

With M3 bolts and nuts, the hornblock is fixed to the frame.

The frames were laser cut, which gives accurate overall dimensions.

No afterwards milling or straighting is therefore necessary. Only a slight touch up with smooth file is sufficient.

The front hornblocks have a cut-out, to give room to the cylinders