These are the cylinder castings that came with the set of locomotive parts.

(They are 90mm long and and have an out side diameter of 66mm. The finished bore is 40mm).

It is the first time for me that I’ll incorporate cast iron cylinders, all my previous locomotives are fitted with bronze cylinders.

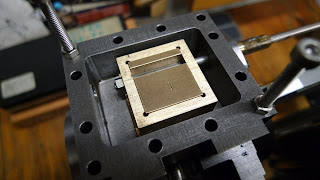

The boring of cylinder, with only light cuts. The set-up in the chuck is far from desirable.

This cast iron is of a good quality (no hard spots) and machining in the lathe was done with carbide cutting tools. Although they are large, they could be clamped in the 3 jaw chuck. This made turning a straight forward job.

During manufacturing of the cylinders there is not much difference with bronze, but the usageof cast iron cylinders on the finished locomotive will be different. This material depends on good lubrication with first grade quality steam oil. Otherwise rust will set in quite quickly. Also all the condensated water has to be removed via the drain cocks after the run I'm told.

Honing the bore with honing stones

After boring out the cylinder to the correct diameter (in this case 40mm, which is small for a 7.25” locomotive) anautomotive honing tool was bought and used for finishing the bore to a smooth surface.

I’ll be using Teflon piston rings of the same design as used in the Mona, Dacre and Didcot. In these locomotives they proofed to be successful and never needed any maintenance yet.

I’ll be using Teflon piston rings of the same design as used in the Mona, Dacre and Didcot. In these locomotives they proofed to be successful and never needed any maintenance yet.

A smooth finish is obtainable

The cylinder port face on the original Prussian T3 (for which these castings are intended) has an inclined angle. In my design this will not be incorporated, so the shaping machine was put in action to remove the surplus of material. The shaper leaves the port face with a very flat surface. The machining marks, left by the tool, are all parallel and in straight lines.

This will be near to perfect to take up a small oil film, on which the valve can glide. The slide valve it self will also be machined in the shaper, but the set up will be arranged so that the grooves left by the cutting tool will be 90 degrees to the ones in the port face. I’ve used this method before with the other locomotives and the slide valves and port faces still look very good after years of service.

The cylinders partly finished, with the covers in front. These were made by Wolfgang years ago and can be used without any problems.

Cutting of the steam ports. They are 4 mm and 8 mm wide and were cut with a small 3.5mm cutter. You'll see no chips in the picture, because I've used a vacuum cleaner to remove them after every cut. This way I kept a clear view on the process and the chips would not clog up the relative deep ports during the cutting process.

Set-up for drilling the steamports

The exact angle was diterment in Solidworks, before drilling!

A lot of holes

The steamports, avoiding the tapped holes.

The light beam shows the exact match of the holes.

Opening out the steamports at the cylinder ends.

Providing clearance in the cylinder covers.

The steam passages.

The cylinder cover.

The portface with steam and exhaust ports.

Fabrication of the steam chest from solid bar.

Drilling and tapping the holes for taking up the steam chest

Bronze valves

The piston rod and gland

Both glands on the covers

The pistons whit the grove for the Teflon piston rings

The Teflon U-shaped ring. This was turned from solid Teflon and sits with a side play of 0.2mm in the grove of the piston. In the depth there is a clearance of approx. 0.4 mm.

They have a sliding fit in the cylinder bore. Expansion due to heat and steam will press them further against the bore; but they also have the possibility to buckle the thin 'legs' of the U shape, if the expansion would be to much so that they wouldn't fit in the grove in the piston.

When the engine is in steam, steam pressure will also get under the ring and will press the ring against the cylinder bore. I have these types of rings successful in service in my 3½" gauge and 5" gauge locomotives for many years now.

The bronze piston in position.

The brown stuff is copper grease, which is used when screwing the studs in the cylinder. Hopefully the studs are removable from the cylinder; even after many years of service.

.